Digital Shop Floor Management creates greater transparency in intralogistics, improves collaboration, and supports a structured continuous improvement process. In logistics centers, at 3PL providers, and across internal material flows, real-time data and performance indicators enable reliable process control and help sustainably increase efficiency and responsiveness.

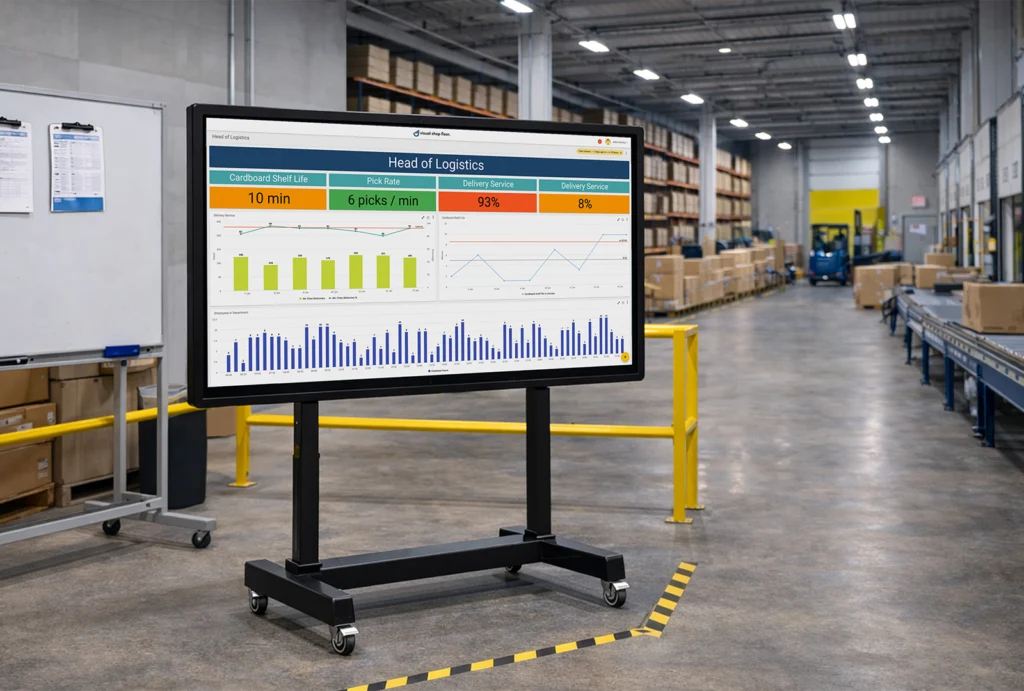

Information board displaying logistics-relevant KPIs for digital shop floor management in intralogistics.

From its origins in manufacturing to a proven model for logistics

Shop Floor Management originated in the automotive industry with the aim of identifying deviations at an early stage, resolving problems directly at the point of occurrence, and implementing improvements continuously. Through clear routines, visual management, and a strong focus on teamwork, the approach became firmly established in industrial manufacturing worldwide.

Today, it is increasingly evident that these principles also deliver significant value in intralogistics. Whether in internal material supply, automated warehouses, or large-scale distribution centers, logistics has become a central component of modern value creation and faces growing demands for flexibility, delivery reliability, and rapid response.

A software-based digital Shop Floor Management system provides a stable foundation in this environment. It creates transparency, supports collaboration across shifts and hierarchical levels, and structures day-to-day operations – making a decisive contribution to embedding stability and continuous improvement sustainably within intralogistics.

Intralogistics in transition – opportunities for greater efficiency

Intralogistics is currently undergoing a phase of intensive transformation. New warehouse and automation technologies, modern picking systems, data-driven control approaches, and flexible working models are significantly expanding the scope of action for logistics organizations. At the same time, e-commerce, omnichannel strategies, and increasingly individualized customer requirements are creating new operational profiles – from high-volume distribution centers to specialized 3PL logistics providers.

This dynamic environment offers companies numerous opportunities to optimize their logistics processes in a targeted manner. Automation can reduce bottlenecks, digital assistance systems support shift operations, and differentiated customer requirements enable new business models. At the same time, the need is growing for a leadership approach that can keep pace with highly dynamic processes and actively involve employees. Transparency, structured task management, and the systematic guidance of change processes are becoming decisive success factors. Digital Shop Floor Management provides the necessary framework to support companies in unlocking these new potentials sustainably.

Why digital Shop Floor Management is essential in intralogistics

To manage the increasing complexity of intralogistics, companies require leadership and organizational structures that are both clear and flexible. Digital Shop Floor Management offers an effective approach to meeting these requirements.

By establishing a consistent and reliable information base for key areas such as goods receiving, picking, and shipping – and by providing continuously updated performance indicators – operational performance and capacity utilization can be assessed on an ongoing basis. Standardized visualizations also promote collaboration across departments, teams, and shifts, which is a critical advantage in large or highly interconnected logistics organizations.

Standardized daily communication in the form of structured meetings across different hierarchical levels increases transparency in day-to-day operations and improves the consistent execution of actions. Combined with proven continuous improvement methods such as PDCA cycles, this creates a closed-loop system of process monitoring and continuous improvement, enabling sustainable efficiency gains.

In this way, digital Shop Floor Management evolves into a strategic leadership instrument that provides orientation, standardizes processes, and actively supports employees in their operational daily work.