Modern Shop Floor Management is built on Industrial DataOps — the intelligent use of live data from manufacturing processes. This approach opens up new paths toward greater process transparency, data-driven improvements, and faster decision-making.

Industrial DataOps for efficient digital Shop Floor Management

Industry 4.0 has long been a reality in many companies. Manufacturing machines, sensors, and automation systems continuously generate valuable data. Capturing and analyzing this data in real time — and linking it with information from other systems such as ERP, MES, or CAQ — is the key to more efficient processes and greater value creation in Shop Floor Management.

Industrial DataOps: From data overload to actionable insights

For a long time, manufacturing machines were viewed as isolated islands. The process knowledge and experience of individual employees were key to efficiency. With the increasing interconnectedness driven by Industry 4.0, it is now possible to understand production systems, intralogistics, planning, and quality assurance as an integrated whole.

This creates enormous potential — but also significant challenges: production data is generated in large volumes, in various formats, and through diverse interfaces. Bringing this data together in a meaningful way, harmonizing it, and making it usable in real time requires a new methodological approach: Industrial DataOps.

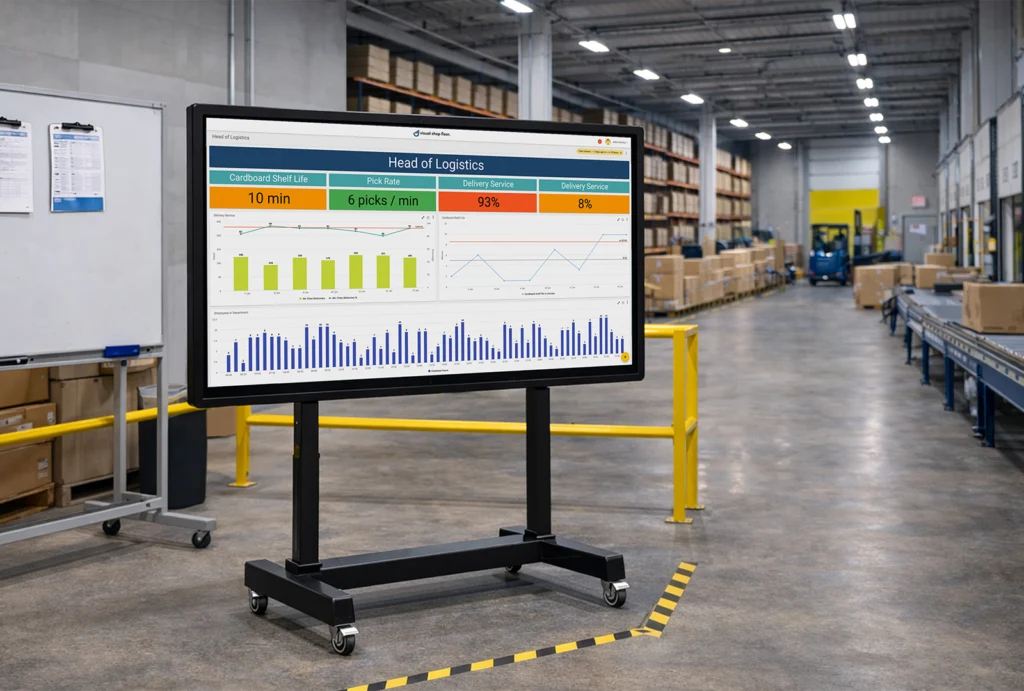

Industrial DataOps refers to the systematic and automated collection, integration, and provision of data from a wide range of sources — from machines and sensors to IT and OT systems, as well as planning and control systems. The goal is a continuous, quality-assured data foundation that is processed and presented in real time in a way that is understandable and usable for all user groups — from shop floor workers to management.

Data driven excellence in digital Shop Floor Management

Digital Shop Floor Management leverages this connected data foundation to make operational processes transparent and controllable. When the principles of Industrial DataOps are consistently applied, traditional Shop Floor Management can be expanded with a powerful data-driven dimension:

Transparency:

Real-time data provides an accurate picture of the current production situation.

Responsiveness:

Deviations and disruptions are immediately detected and can be specifically addressed.

Sustainable Improvement:

Methods such as PDCA cycles, task management, or event-based handling can be systematically supported by data.