Dynamic

Maximum flexibility and customizable – self-configurable through low-code

Practice-oriented

Developed in cooperation with industry partners – maximum user-friendliness

Enterprise ready

Designed for use in medium-sized and large enterprises – across locations

DATA MANAGEMENT

to gain valuable information

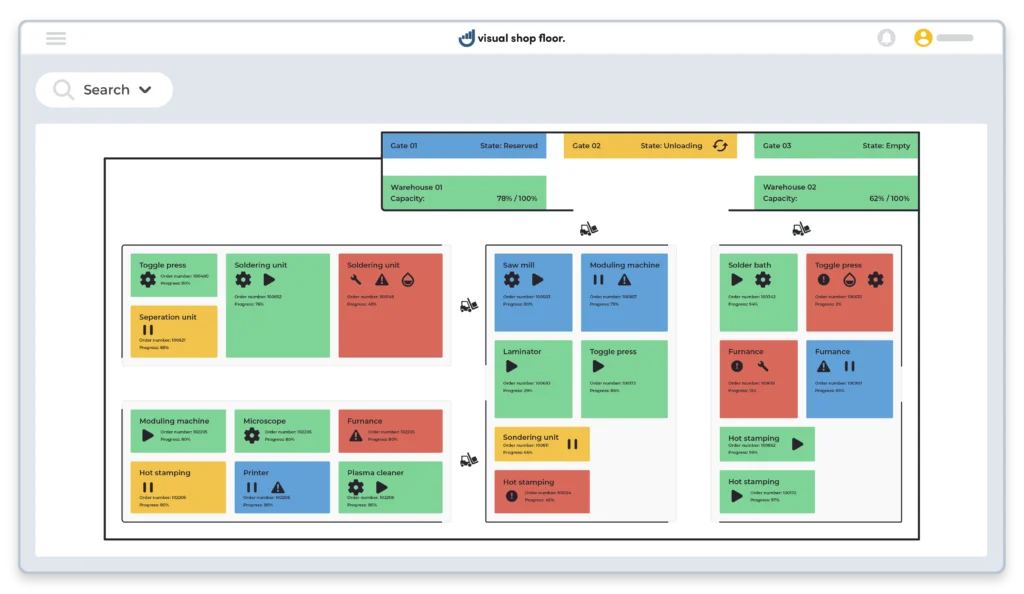

Use all relevant data in one place

DETECT deviations and

malfunctions at an early stage

Inform your employees in the operational area

Don't miss a thing with automated notifications in real time

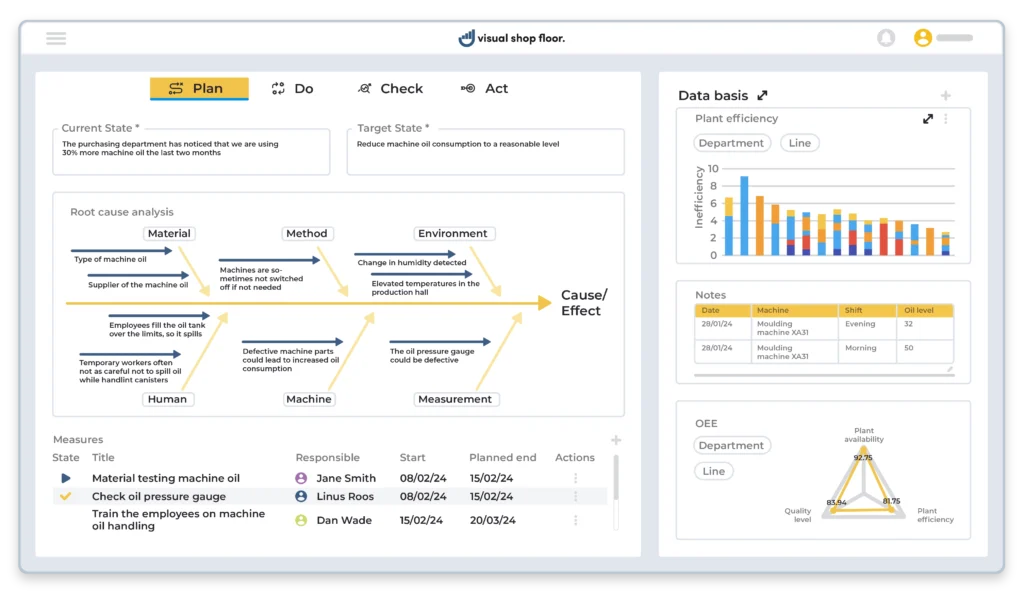

ACT promptly and in an organized manner

Take meetings to a new level

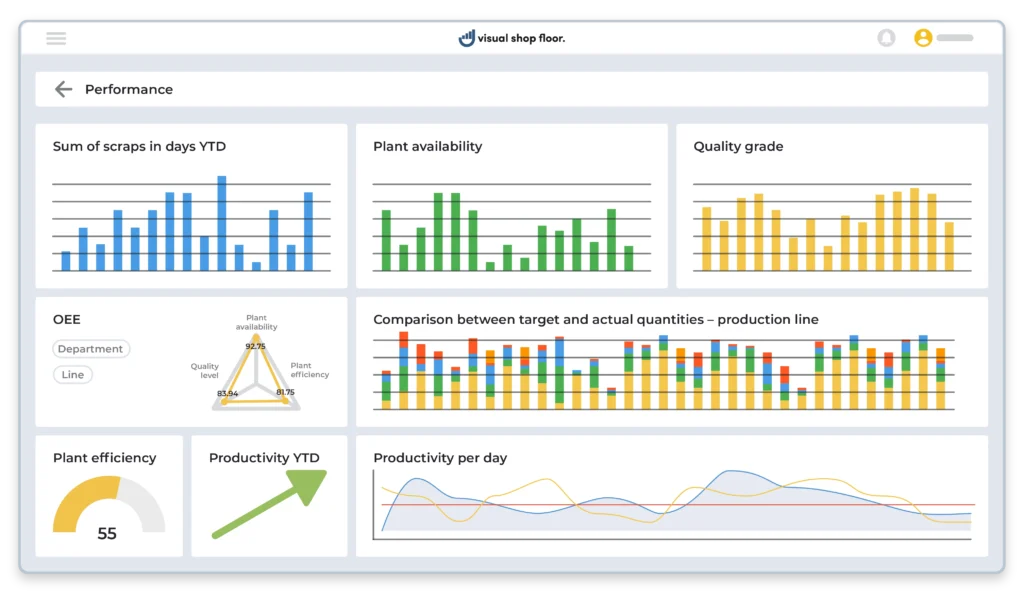

OPTIMIZE processes systematically and sustainably

Improve the quality and efficiency of your processes and reduce the risk of errors or quality problems

Visual Shop Floor adapts flexibly to your needs and integrates perfectly into the existing system landscape and your organizational structure. As a fully integrated platform for increasing Operational Excellence, Visual Shop Floor is the ideal link for smooth collaboration between departments and within the team.

The greatest added value for you as …

Production and Logistics Manager

Visual Shop Floor actively supports you in identifying disruptions and deviations in the processes and thus in recognizing the need for action at an early stage. Through the targeted initiation of measures, regular operations are restored promptly, resource utilization is increased, and adherence to schedules is maintained.

Operational Excellence Manager

Visual Shop Floor is the ideal platform for designing the CIP process in a contemporary way and establishing a positive improvement culture together with your employees. With continuously updated key figures, combined with task management and established methods from LEAN management, you create the ideal basis for a flexible way of working and for the motivation of your employees as a central driver for process optimization.

Lean Manager

Visual Shop Floor offers a wide range of possibilities to improve efficiency, productivity and quality in production and logistics. Through the systematic, software-based application of established methods, your company's LEAN initiatives are strengthened and operational efficiency is increased, giving your company a sustainable competitive advantage.

IT Manager

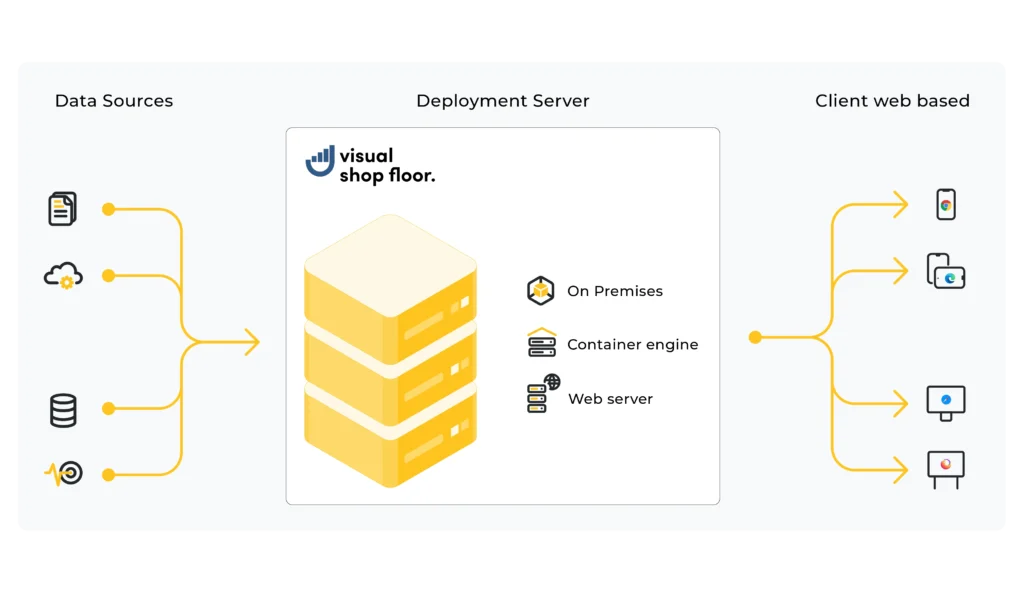

Visual Shop Floor enables you to use the full potential of data to optimize production and logistics processes. Existing data sources and systems are connected via flexible connectors and the data is easily linked and prepared. This creates the basis for flexible mapping of company-specific processes.

Visual Shop Floor is designed for the use in medium-sized and large industrial companies. In addition to the wide range of functions for Shop Floor Management, this requires a number of technical functions that enable flawless use as well as smooth integration into your company's system landscape. Whether process monitoring for one department or establishing global standards across multiple sites: Visual Shop Floor adapts to your needs and enables you to exploit the full potential of your company.

Manage users easily and flexibly via the integrated user management in Visual Shop Floor.

With support for multiple languages and the ability to add any language easily and with minimal effort, Visual Shop Floor speaks the language of your employees, eliminating potential barriers.

Use Visual Shop Floor across sites throughout the entire group – establish global standards and keep the overall view.

Scalability

With support for container technology and enterprise platforms, Visual Shop Floor is highly scalable and can therefore be flexibly adapted to your specific requirements – start small and grow step by step.

System monitoring

Integrate Sie Visual Shop Floor into your company's service monitoring and thus ensure smooth operation. Via a service API, any faults are quickly detected, localized and eliminated at an early stage.

Data exports

All data stored in Visual Shop Floor can be accessed and used via an export API. This provides the prerequisite for seamlessly integrating your Shop Floor Management into your system landscape and automating it to the maximum.

Schemes

As a web-based application following the Responsive Web Design approach, Visual Shop Floor can be used on various end devices without any additional administration effort: whether smartphone, PC or Shop Floor Board: with Visual Shop Floor, your employees are very close to what is happening in your production and logistics environment – always and everywhere.

Integrate Visual Shop Floor with your authentication infrastructure to reduce administrative overhead. Single Sign-On via OAuth 2.0 provides your employees with an optimal user experience.

With the introduction of Visual Shop Floor, downtimes and production interruptions have become less frequent. If problems arise, we can now react more quickly.

Patrick Abfalterer

Head of Automotive Assembly, Intercable

Visual Shop Floor is used in almost 25 plants around the world and is an indispensable tool for providing our employees with targeted information, recognizing potential faults before they occur, and deriving the right actions from them."

Georg Bachmann,

Director Global Business Systems, GKN Powder Metallurgy

With Visual Shop Floor we no longer talk about yesterday's problems in our morning meetings, but find answers to today's questions."

Christoph Beikircher,

Head of Lean Management, Alupress

Visual Shop Floor offers our employees a uniform platform for identifying problems at an early stage, solving them sustainably and thus for the continuous improvement of processes."

Markus Tichai,

Head of Production-IT – Operations Europe, CeramTec

Visual Shop Floor allows us to recognize deviations and challenges at an early stage in order to derive improvements and thereby increase productivity."

Adrian Scherrer

Team Leader Digital Transformation, SFS Intec

With Visual Shop Floor we no longer talk about yesterday's problems in our morning meetings, but find answers to today's questions."

Christoph Beikircher,

Head of Lean Management, Alupress

With the introduction of Visual Shop Floor, downtimes and production interruptions have become less frequent. If problems arise, we can now react more quickly.

Patrick Abfalterer

Head of Automotive Assembly, Intercable

Visual Shop Floor is used in almost 25 plants around the world and is an indispensable tool for providing our employees with targeted information, recognizing potential faults before they occur, and deriving the right actions from them."

Georg Bachmann,

Director Global Business Systems, GKN Powder Metallurgy

Visual Shop Floor offers our employees a uniform platform for identifying problems at an early stage, solving them sustainably and thus for the continuous improvement of processes."

Markus Tichai,

Head of Production-IT – Operations Europe, CeramTec

Visual Shop Floor allows us to recognize deviations and challenges at an early stage in order to derive improvements and thereby increase productivity."

Adrian Scherrer,

Team Leader Digital Transformation, SFS Intec

Your Privacy is important to us. We only use technical cookies.